What we learned in Materials and Processes

Stress-Srain curves are useful when trying to understand properties of certain metals and plastics. To calculate the curve of the Stress-Strain Curve, you must first find the Stress and Strain separately and divide the Stress by the Strain.

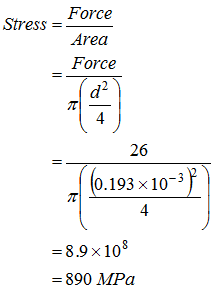

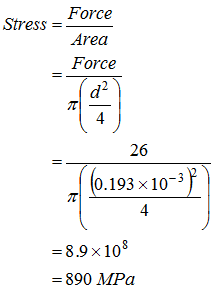

To calculate the stress, you divide the force acting on the object and divide that by the CSA (cross-sectional area)

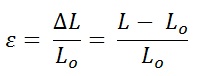

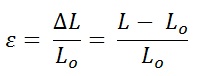

To calculate the strain, you must divide the original length minus the final length by the original length

Once you have calculated both the Stress and the Strain, divide the Stress by the Strain

When trying to find CSA or force, you can set the Stress/Strain to the modulus of elasticity. The modulus of elasticity, or Young's modulus is a number that shows a materials resistance to deforming under a load.

In a stress-Strain Curve, there are different points on the curve that explain what is going on with the material. The Stress is plotted on the y-axis and the Strain is plotted on the x-axis. Before the curve reaches the Yield point, it is in the elastic phase. In this phase, if the force discontinues, the material will not be permanantley deformed

Once the force has acted on the material past the yield point, it movees into the plastic deformation stage. At this point, even if the force stops, the material will be permanentley deformed. Moving through the plastic deformation stage, the material gets to the UTS or the ultimate tensile strength point, which exhibits the point at which the material can not maintain a force greater than this point. After this point, the material enters the fracture point and begins to break.

There are 5 mechanincal properties of Metals.

Strength: The ability to resist deformation under load

Hardness: The ability to resist deformation, penetration and scratching

Ductility: The ability to deform under load without breaking

Toughness: The ability to resist shock loading

Stiffness: not flexible; ability to resist bending